Since it was founded in the 1960s, Santos' mission has been to create quality furniture and kitchens that are beautiful and functional, but above all, resistant to daily use and to the passage of time. To ensure durability and quality, Santos subjects its kitchens to numerous checks and laboratory tests to test the materials and components.

These tests, carried out in accordance with various standards, are designed not only to meet the minimum requirements set out in European regulations, but also to exceed them, in order to offer you the highest quality furniture. In addition, the Spanish company has numerous European certifications and carries out additional tests to ensure the longevity of each kitchen component.

GS certified kitchens

GS certification (from the German “Geprüfte Sicherheit”, controlled safety), is the only one in Europe which, since 1977, has verified compliance with all quality and safety standards for equipment and products. It’s a voluntary certification, recognised as a guarantee of good quality and reliability throughout Europe. The procedure covers all stages of manufacturing and involves a thorough analysis, including mechanical and chemical safety, and is responsible for evaluating the production system, ensuring that the manufacturing facilities have been inspected and are compliant.

In order to obtain GS certification, a laboratory accredited by TÜV Rheiland has subjected Santos kitchen furniture to multiple tests, both on complete modules and on independent elements, which aim to test many elements. For example: the stability and safety of the door hinges, the reaction of fixing systems for tall units in the event of overloading, the strength of the glass or the analysis of the chemical components of the kitchen units.

All Santos brand products have been GS certifiedsince 2015, a guarantee for users that Santos manufactures quality furniture, and that it will not endanger their safety or health, either through intended use or misuse.

Quality control of the panels

The panel is a structural element that forms the basis of the furniture. Therefore, the useful life of a quality kitchen largely depends on its quality and resistance. The panels used by Santos are subjected to stringent weight, bend and scratch tests, simulating conditions of use and wear equivalent to the life of the kitchen.

Santos carefully inspects and analyses each batch received at its factory, checking that the tone and colour of the panel is correct, as well as testing its density and thickness to ensure compliance with European standards.

Following this, the mechanical properties of the batch are assessed. These include flexural strength, surface picking strength, perpendicular tensile strength, screw removal strength and scratch resistance.

Quality control of edgebands

As with the panels, each batch of edgebands received at the factory is inspected for colour and dimensions and tested to ensure quality, strength and durability. Only edgebands that pass these rigorous tests are used in Santos quality kitchens.

The Santos laboratory carries out washability and friction tests to ensure resistance to cleaning, and verifies the presence of a primer coat.

Quality control of chamfered parts

The correct chamfering of the panels is one of the most important factors in the conservation of quality kitchen furniture, as it allows the interior of the rooms to remain isolated and protected from the influence of liquids and humidity. Even waterproof panels, i.e. those that are resistant to moisture, cannot offer this performance if they are not properly chamfered, especially in problem areas such as the sink, dishwasher or refrigerator.

Santos rigorously controls the chamfering process, ensuring optimum levels of adhesion and durability.

The quality laboratory requests anonymous orders from the factory to analyse the different materials with which the chamfering machines operate. It then carries out tests for adhesion and bonding, resistance to immersion in liquids and steam, and resistance to ageing.

Quality control of modules with shelving

To ensure that these shelf modules do not break or tip over due to weight, Santos carries out overload tests in accordance with the regulations in force. These are tailored to the characteristics of each module and go beyond the required test times of up to several months.

In addition, the supports are subjected to impact tests to assess their resistance to fractures that could lead to the accidental detachment of the shelves. At the same time, Santos carries out tests to ensure the strength of the wall fixing mechanisms. These tests validate that the fastening is suitable for the volume of the module, and prevent any detachment.

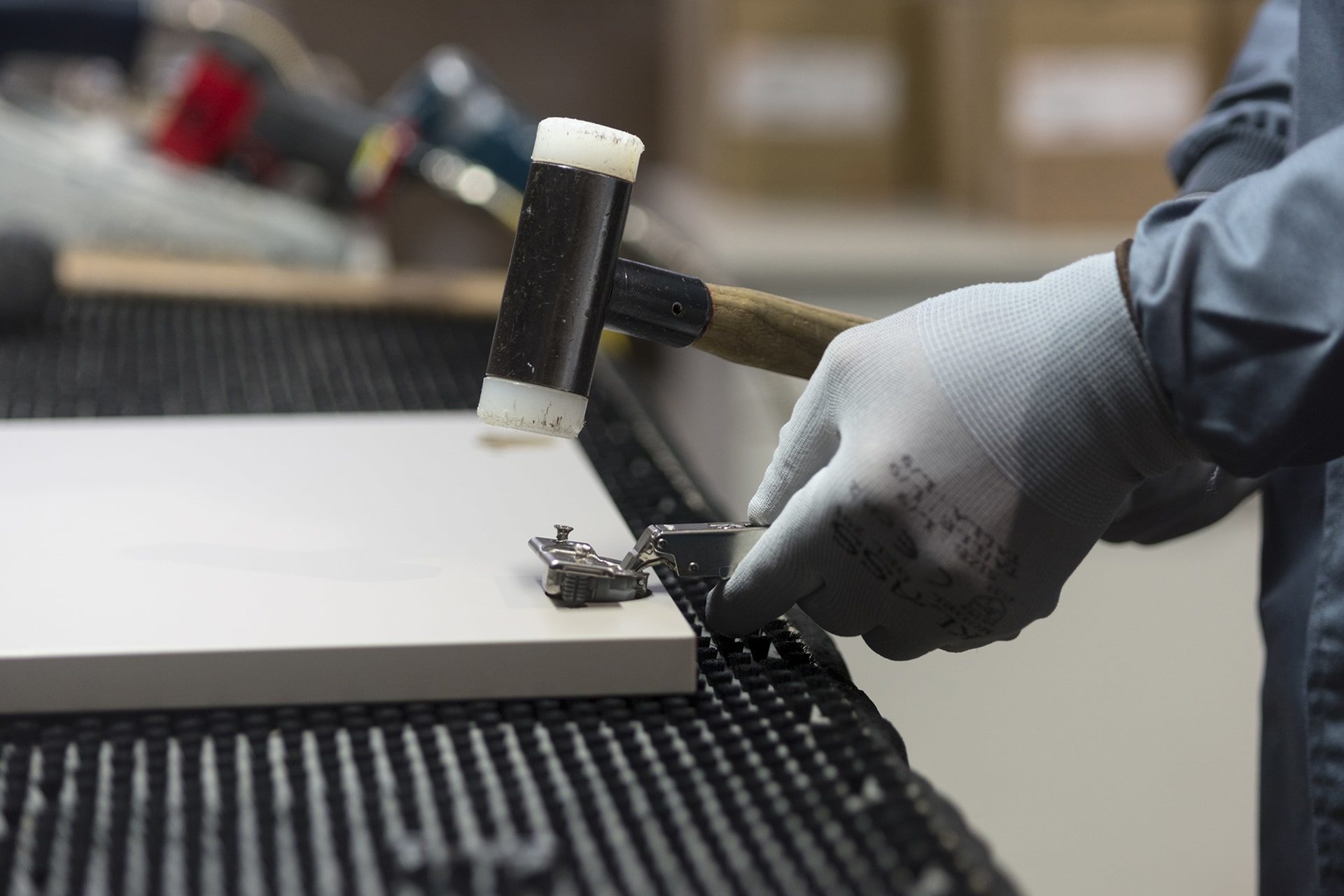

Quality control of fittings and mechanisms

Handles, fittings and opening, closing and braking mechanisms are the most frequently used components in the kitchen and are largely responsible for a smoother, more comfortable and more pleasant use. They all work every time you use the furniture, which is why it’s important to ensure their durability.

Santos carries out checks and laboratory tests on all the metal components of its quality kitchens (handles, hinges, rails, screws, bungs, etc.) to ensure that they are resistant to corrosion and wear (abrasion, friction, deterioration).

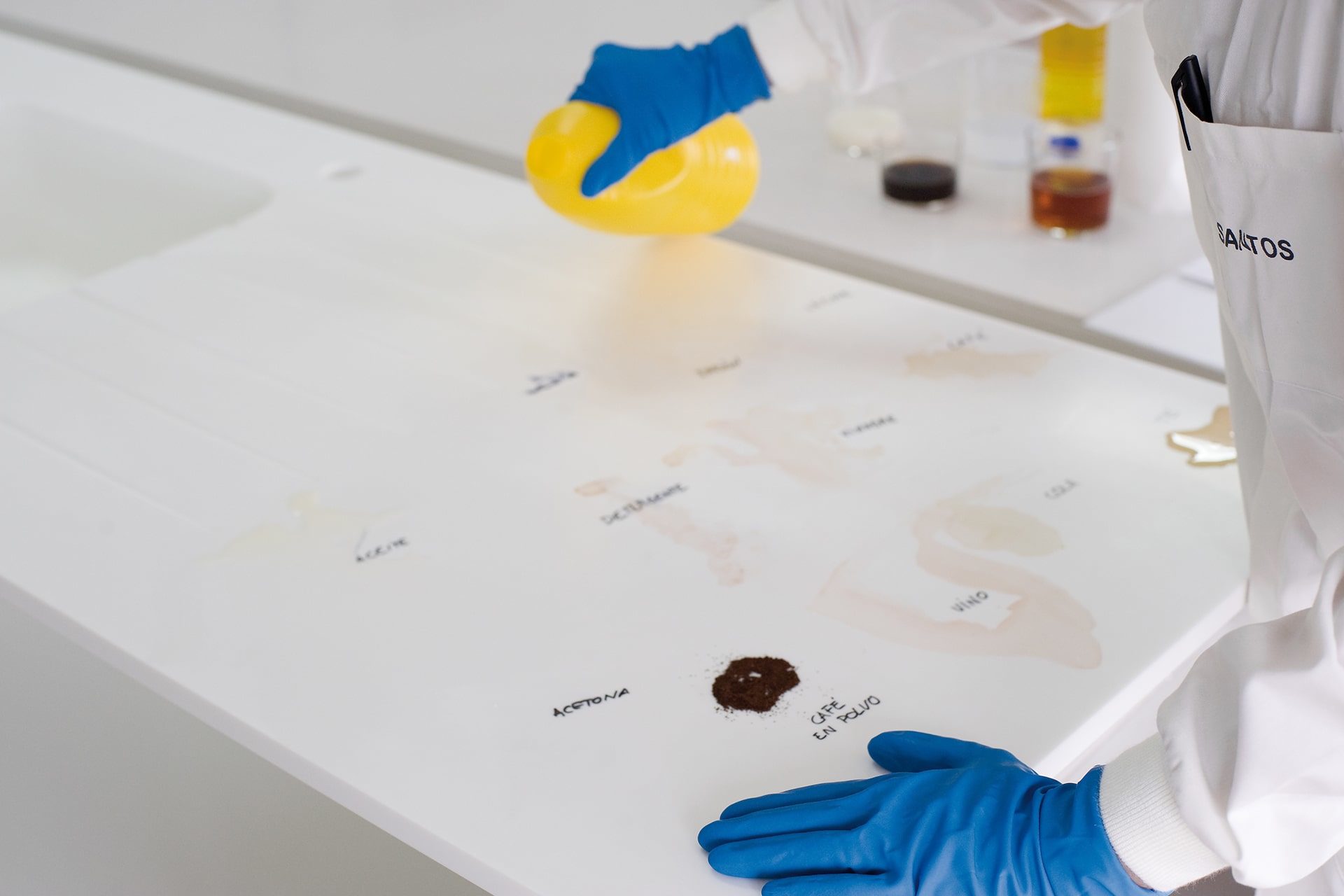

Quality control of worktops

Quality worktops are one of the most important elements in the kitchen, not only from an aesthetic point of view, but also because they provide the user with a comfortable work surface for preparing food. That’s why Santos prioritises resistance and safety and only includes materials that have passed strict quality controls in its catalogue.

The brand will therefore ensure several things: compliance with food use regulations, resistance to food contact and cleaning products, reaction to heat and cold, and resistance to impact and shock.